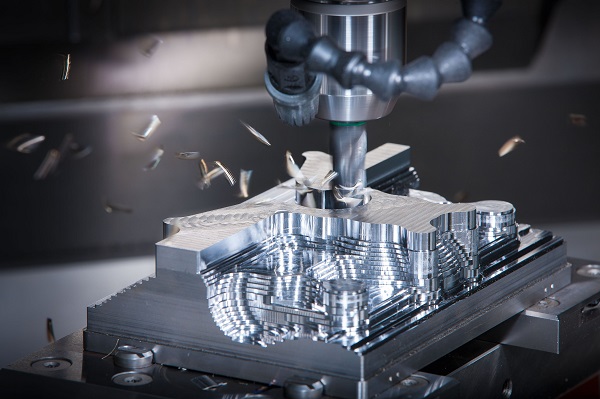

The essential distinction between the two cycles is that with CNC machining we are diminishing material as we start with a froth block for instance, cutting it away; while with 3D printing we are layering on and adding material until we get the eventual outcome thusly called added substance producing. The 3D printer utilizes similar materials that make up the part it is making for example ABS PLA and nylon, yet it cannot switch between materials though in CNC machining we can utilize a few kinds of materials, frequently adding extra materials toward the end. Nonetheless, machining can be chaotic – Sometimes we have to utilize a residue authority while working a CNC switch machine to get all that overabundance made in the penetrating, cutting and processing measure while there is less waste material produces in printing and the entire cycle is less boisterous.

CNC machining can be more exact giving more exactness on the grounds that the machines have a higher capacity to bear heat. It can likewise bring about a much smoother cleaned surface completion given the materials to be machined. 3D printers can really misshape a section, curve and twist if utilizing a lot of warmth on the layered material so if extraordinary perfection is required the Cheshire Seals 3D printing will miss the mark. 3D printing is commonly a simpler more advantageous cycle and not as work serious as CNC machining since with machining we have to program, compose a G-Code, set up various instruments and speed, choose cutting way and tidy up after. Notwithstanding, the part size assumes a function as bigger parts take more time to be printed adding layer by layer. By and large, 3D printing can aid a few instances of prototyping of high mathematical unpredictability where the switch instrument cannot reach inside the shape.

3D printers can just utilize the territory of the printer bed itself to manufacture the parts. Thusly if enormous scope parts are required they probably would not have the option to fit in there. It is likewise not suggested for large scale manufacturing as the materials are significantly more costly and set aside substantially more effort to create. In this manner, 3D printing is more fitting and savvier for low volume creation. CNC machining can infrequently run unattended and requires gifted administrator while with 3D printing we can undoubtedly run the cycle unaided and it requires negligible preparing for its administrator. Be that as it may, CNC machining is a more seasoned practice (began during the 40’s) at present actually has a more grounded position in the assembling business. 3D printing is moderately new and as yet developing to be more helpful and versatile and still cannot be a full swap for machining.